The Intricate Functionalities of Metal Punches and Die

- Industrial Engineering |

- Apr 19, 2018

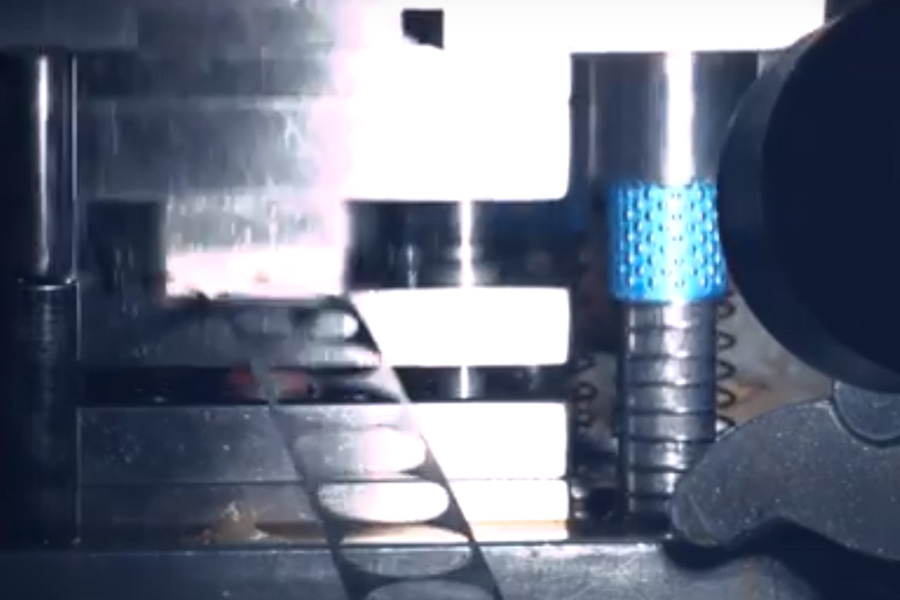

Die is a specialized tool that is used in precision metal stamping industry to cut and then shape a material according to the preset design. Just like how molds work, the punches and dies are also custom designed according to each project that is on hand. The products that are made with dies simply range from paper clips to really complex pieces that are used in the latest technology. The metal stamping industries rely heavily on metal punches and die for core functionalities. Here are some of the relevant details that highlight intricate functionalities of these important tools.

The operation of punches and die

The sheet metal used for metal stamping is usually known as stock or strip. The punch is fit in a punch holder and it is then tightly bolted to the press ram and the die is also bolted on press table. As the work progresses, it is the punch that penetrates the stock or strip and as the press ram stroke returns the stock is lifted along with the punch. However, striper plate is used to remove it from the punch. In this way the primary action takes place for metal stamping.

The types of dies used

The components are usually incorporated in the blanking or piercing die. At times, the die and punch positions are changed in situations when opening in bolster plate is small to permit the finished product and the pass through the opening.

Combined dies

This combines the principles of inverted dies and conventional dies in one station. This is the type of die that may produce a work piece that is blanked and pierced at one station and in one operation as well. In this die, the piercing punch is tightly fastened to the punch holder in a conventional position. The blanking die and punch are mounted in an inverted position.

Inverted dies

These dies are designed with die block that are fastened to punch holder, and then the punch is fastened to the die shoe. The blank is then sheared from the strip during downward stroke of a ram. The shedder and blank are then again forced back into die opening, and this helps load a compression spring in die opening. At the same time, the punch is also forced through scrap string and a stripper is loaded after it is compressed. This is how the inverted dies function.

Progressive dies

Progressive dies are not your regular dies can be designed for every project. However, these dies are designed for specialized projects. These are designed with two or more stations that are arranged in a sequence together. Every station performs a set of predefined operations on the work piece so that once the last operation is complete the work piece is complete. Therefore, each stroke from the ram will produce a finished part accordingly. In this die, the list of operations possible is way too long, and in most cases it largely depends on the creativity of the designing team.

A crucial requirement for industries

Metal punches and dies are specifically designed for asset of project that comes up. Well, there are several aspects that are considered such as the raw material, production needs, delivery time, length of a project, the product being stamped, and so on. Industries that need new products or components have to hugely rely on the precision metal punches and die. As a result, this has become one of the crucial requirements for several industries.

Choose the right designers

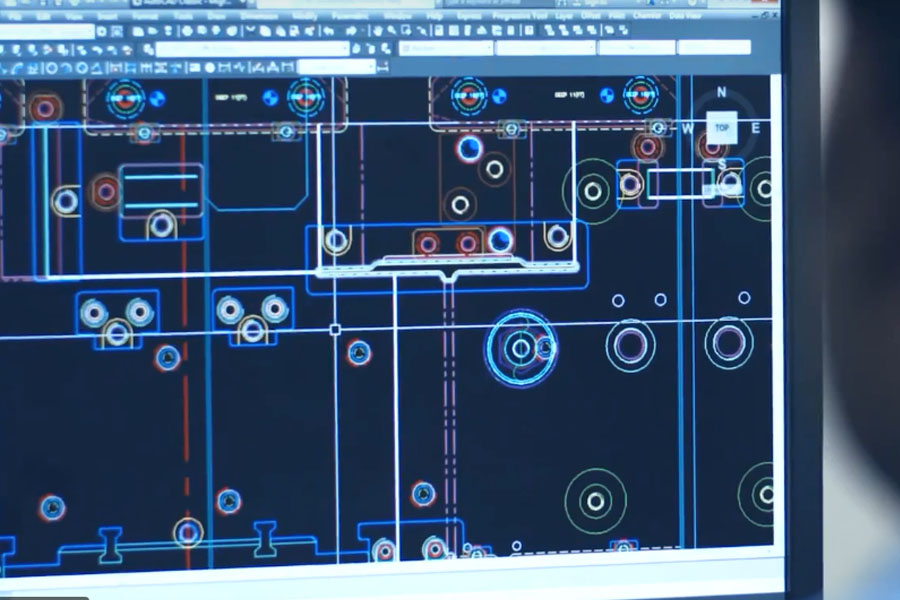

In order to get the best results, you need to choose designers that have experience with metal punches and die. Some of the designers or die makers are new to this field and may not necessarily be equipped to handle the intricacies of this project. However, you need to make sure that only experienced professionals in this field are assigned the job of designing. Designing the custom metal punches and die is an expert level job and needs a lot of attention to detail, good planning, good coordination with the team, and so on. So make sure that you choose only the right designers for your project.

Eigen a perfect place for metal punches and die

Eigen is experienced with over 14 years in the field of precision metal stampings. The suppliers have in house tool designing and developing process that works on metal punches and die designs. Once a requirement is received, the creative minds start working on the best possible design approach to make a project economic. The professionals working here are involved with regular training to help them be up to date with the trends in this field. Eigen has a practice of ensuring the clients are kept happy in all the projects that are handled here.

Ujjwal handles crucial roles like AGM Marketing, researcher, and is an author for KDDL – Eigen. He currently works with Eigen for implementing proven techniques and strategies for marketing plans on online and offline platforms. An expert in efficiently executing SEO, SEM, email marketing, social media marketing, PR marketing, Print campaigns, etc. Ujjwal has coordinated an efficient marketing team on various creative campaigns and programmatic buying to support various digital cross-promotion efforts. Implement efficient search optimization strategies with the help of collateral material and metrics.

In his former years, Ujjwal has years of experience in a managerial role for several reputed companies. His years of experience combined with the flair of writing help him come up with result oriented strategies for Eigen.