Is Die Stamping Essential for Sheet Metal Forming?

- Design and Engineering |

- Oct 23, 2019

The interesting question that we will be discussing in this article is – Is die stamping essential for sheet metal forming? Before we find an answer to that question, let us first understand the basics of what is metal stamping? Types of metal stamping? What is sheet metal forming? And what are the different types of processes in metal forming?

Metal Stamping:

In metal stamping flat metal sheets are fed in the stamping press which is then transformed into different desired shapes. Stamping process is also called pressing. This process includes a number of techniques like punching, blanking, piercing, coining, embossing and so on.

The design for metal stamping has to be precise so that each punch on the metal sheet will result in optimal part quality. Die stamping components can have curved bends and all the bends can be done at once. Progressive die stamping is one of the major techniques used in metal stamping die.

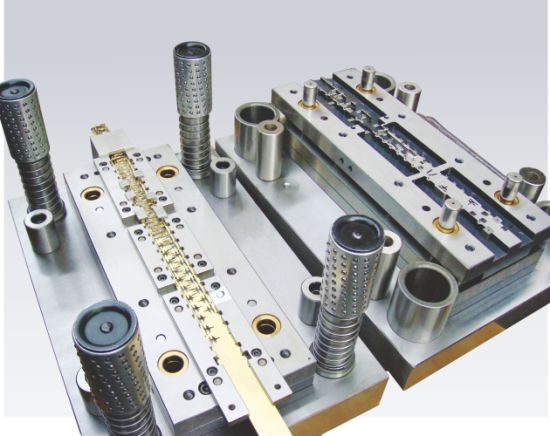

Progressive Die Stamping:

Progressive die stamping is a process that performs in a progressive manner on a series of stations and most importantly uses ‘die’ for stamping. Once the die is placed on the stamping press, the metal sheets unrolls itself steadily and automatically moves into the stamping press one after the other till it reaches the final station. During this process the metal moves through the die with precision and with each stroke it performs cutting, punching, bending, coining, trimming, shaving and various other techniques that are used simultaneously during the process to achieve the final metal part. The finished parts are then ejected from the die. In progressive die stamping even the most complex stamping components can be achieved and that is why this stamping technique is the best when it comes to high volume production, quick setup, fast turnaround and less overall cost. Hence, progressive die stamping is a fast process with a very limited wastage.

Now, that we have understood metal stamping and the technique of progressive die stamping, we will now have a closer look at sheet metal forming and its processes.

Also Read: Get to Know 5 Types of Dies used in Sheet Metal Die Stamping

Sheet Metal Forming:

Sheet metal forming is a process in which a force is applied on a flat metal sheet, and with the force the sheet modifies its geometry, without removing any material from it. During this process, the metal sheet goes through stress which makes it suitable for bending and stretching for a variety of complex shapes. This process does not require any machining or a die. Formed parts consist of straight bends that are put in one at a time and these parts can be either extremely small or large. Tooling in sheet metal forming is standardized and can be used in several applications. Sheet metal forming is used in almost every sector of industrial manufacturing like- home appliances, automotive, aircraft, food and beverages and so forth. In short, the process of manufacturing a 3D part from a flat metal sheet is known as sheet metal forming.

EXPLORE OUR DIE METAL STAMPING SERVICES

Process of Sheet Metal Forming:

Bending:

Bending is when a force is applied on a piece of metal sheet which causes the sheet to bend at an angle, forming the desired shape. It is usually performed on a machine called a press brake that can be operated either manually or automatically.

Roll Forming:

This is a process in which a metal sheet is progressively shaped through a series of roll stations. As the sheet moves from one roll station to the other it goes through deformation and eventually bends.

Spinning:

Spinning is a metal forming process in which a metal sheet is rotated by applying force on one side for the formation of cylindrical parts. Spinning is performed at high speeds to form the desired shape.

Also Read: Overview of Sheet Metal Press Tool Design in the Manufacturing Industry

Deep Drawing:

In Deep drawing the metal sheet is stretched into the desired shape by a tool that pushes the sheet downwards into a die cavity. This leads to deformation which is in the form of a cup-shaped part.

DISCUSS YOUR DIE STAMPING NEEDS? CONTACT US!

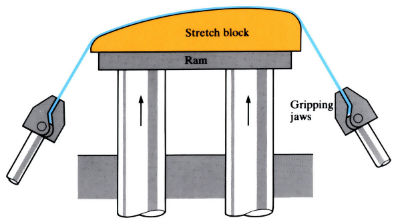

Stretch Forming:

A piece of metal sheet is stretched and bent on a stretch press and is simultaneously formed into large contoured parts.

There are many companies around the world today, that perform sheet metal forming directly from CAD model without the use of any die stamping. High-end robots are used to perform these tasks, these robots use the stylus to shape the desired part and this helps to reduce the lead time. Therefore, it can be concluded that die stamping is not essential for sheet metal forming.

Ujjwal handles crucial roles like AGM Marketing, researcher, and is an author for KDDL – Eigen. He currently works with Eigen for implementing proven techniques and strategies for marketing plans on online and offline platforms. An expert in efficiently executing SEO, SEM, email marketing, social media marketing, PR marketing, Print campaigns, etc. Ujjwal has coordinated an efficient marketing team on various creative campaigns and programmatic buying to support various digital cross-promotion efforts. Implement efficient search optimization strategies with the help of collateral material and metrics.

In his former years, Ujjwal has years of experience in a managerial role for several reputed companies. His years of experience combined with the flair of writing help him come up with result oriented strategies for Eigen.